-

씨"우리는 8 일 전에 그것을 받았고 모든 것이 매우 잘 되었고 당신에게 감사하고 우리가 더를 가지고 있는 것에 행복합니다 이미 공장에서 제품.우리가 당신과 의사소통하는 " 어떤 것

씨"우리는 8 일 전에 그것을 받았고 모든 것이 매우 잘 되었고 당신에게 감사하고 우리가 더를 가지고 있는 것에 행복합니다 이미 공장에서 제품.우리가 당신과 의사소통하는 " 어떤 것 -

씨"하와이 케리, 우리는 토론자단에 참가하여 약간의 추가적 시험을 했고 그 결과로 행복합니다 "

씨"하와이 케리, 우리는 토론자단에 참가하여 약간의 추가적 시험을 했고 그 결과로 행복합니다 " -

부인매우 만족합니다 좋은 제품입니다. 빠른 배송과 모든 것이 매우 잘되었습니다.

부인매우 만족합니다 좋은 제품입니다. 빠른 배송과 모든 것이 매우 잘되었습니다.

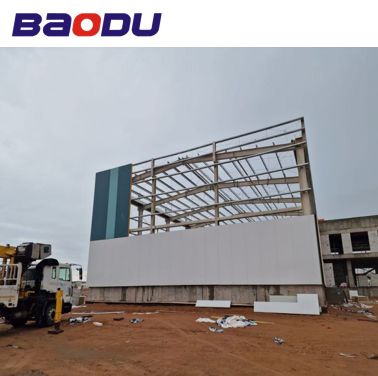

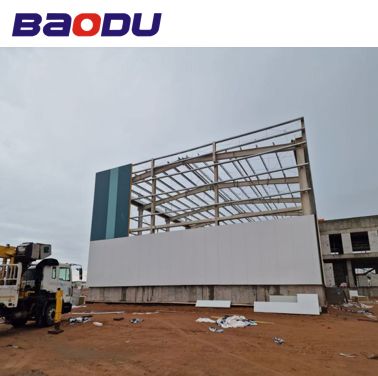

Canada Project Steel Structures Commercial Prefab Warehouse Metal Buildings Sheds Construction

| 원래 장소 | 헤베이, 중국 |

|---|---|

| 브랜드 이름 | BAODU |

| 인증 | ISO9001,CE |

| 모델 번호 | 강철 창고 |

| 문서 | Baodu Company Profile.pdf |

| 최소 주문 수량 | 토론 가능 |

| 가격 | Reasonable |

| 포장 세부 사항 | 일반적으로 강철 구조의 경우 강철 프레임 포장을 사용하여 상품을 깨지지 않도록합니다. 샌드위치 패널 및 컬러 스틸 시트의 경우 플라스틱 포장을 사용합니다. 고객이 특별 포장이 필요 |

| 배달 시간 | 30 일 |

| 지불 조건 | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| 공급 능력 | 한 달에 10000 평방 미터/평방 미터 |

무료샘플과 쿠폰을 위해 나와 연락하세요.

whatsapp:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 제품 이름 | 캐나다 프로젝트 강철 구조 상업용 조립식 창고 금속 건물 창출 건설 | 구조 | 강철 구조 프레임 용접 |

|---|---|---|---|

| 예어 | 저장소를 구축하는 철골 구조물 | 구조 유형 | 장거리 격자 구조 |

| 용법 | 워크숍 창고 건설 사무소 | 드로잉 디자인 | SAP2000 /AUTOCAD /PKPM /3D3S /TEKLA |

| 디자인 스타일 | 현대식 | 벽 및 지붕 | 샌드위치 패널; 컬러 스틸 시트 |

| 이차 구조 | 도리; 중괄호; 무릎 브레이스 등 | 처리 서비스 | 굽힘, 용접, 해조, 절단, 펀칭 |

| 강조하다 | prefab steel warehouse buildings,commercial metal building sheds,Canada project steel structures |

||

As a leading manufacturer and exporter of pre-engineered steel buildings (PEB) and custom steel structures, we provide engineered solutions for a vast range of industrial, commercial, and institutional applications worldwide. Our focus is on delivering superior strength, design flexibility, and cost-efficient construction without compromising on international quality and safety standards.

Our structures are systems built with precision-engineered components:

- Primary Framing: Main rigid frames (columns and rafters) are fabricated from high-tensile steel (Q345B compliant with ASTM A572 Gr. 50 or equivalent). We offer clear-span designs up to 100m+ and multi-span configurations for maximum interior space flexibility.

- Secondary Framing: Purlins and girts are cold-formed Z or C-sections from Galvalume-coated steel (AZ185 or ASTM A792), designed for optimal load transfer and fast cladding attachment.

- Cladding & Roofing: We supply a variety of profiles and materials:

- Roof/Wall Panels: 0.4mm - 0.8mm thick corrugated or trapezoidal sheets, available in Galvalume (SEAZ/Z275), pre-painted steel (PPGI), or color-coated aluminum.

- Insulation Options: Rock wool, fiberglass, or PEF foam sandwiched panels for excellent thermal and acoustic performance (U-value options available).

- Connections: High-strength galvanized bolts (Grade 8.8 or 10.9) and accessories ensure secure and swift assembly.

- Unmatched Design Flexibility: Our in-house engineering team uses advanced software (e.g., STAAD.Pro, Tekla) to design structures to your exact dimensions, load requirements (dead, live, wind, snow, seismic), and local building codes (IBC, Eurocode, etc.).

- Exceptional Durability & Protection: All structural steel is shot-blasted and primed. We offer Hot-Dip Galvanizing (according to ISO 1461, 100-150μm) for superior corrosion resistance in coastal or industrial environments. Advanced paint systems are also available.

- Cost and Time Efficiency: The pre-engineered system reduces material waste, foundation costs, and on-site labor time by up to 40% compared to traditional construction. Components arrive pre-drilled and pre-cut for a bolt-up assembly.

- Sustainability: Steel is 100% recyclable. Our manufacturing process optimizes material use, contributing to a lower carbon footprint for your project.

We understand that compliance is non-negotiable for international projects.

- Certifications: Our manufacturing facility is ISO 9001:2015 certified. We can provide Mill Test Certificates for all raw materials and products are manufactured to meet CE.

- Quality Control: Rigorous QC checks are implemented at every stage:

- Incoming Material Inspection

- In-Process Inspection (cutting, welding, drilling)

- Final Inspection (dimensional accuracy, coating thickness, packaging)

- Third-Party Inspection welcome and accommodated.

Our solutions are tailored for diverse sectors:

- Industrial: Manufacturing plants, warehouses, logistics centers, distribution hubs, aircraft hangars.

- Commercial: Retail supermarkets, showrooms, shopping malls, office buildings.

- Agricultural: Machinery storage, hay barns, livestock buildings, poultry farms.

- Institutional: Sports halls, gymnasiums, schools, community centers.

- Specialized: Multi-story buildings, car parking shades, disaster relief shelters.

We are more than just a seller; we are your project partner.

- Phase 1: Design & Quotation: Provide us with your requirements (site location, intended use, dimensions, preferred specifications). We will provide detailed layout drawings, a 3D model, and a competitive quotation.

- Phase 2: Engineering & Fabrication: Upon order confirmation, we deliver full shop drawings for approval and proceed with fabrication under strict QC protocols.

- Phase 3: Packaging & Shipping: Components are bundled, crated, and marked for easy identification. We have extensive experience in containerization and break-bulk shipping, handling all export documentation efficiently.

- Phase 4: Support: We provide comprehensive erection manuals and are available for technical support during the assembly phase. On-site supervision can be arranged.

We offer comprehensive support including basic design, facilities procurement assistance, and installation guidance.

Our strict quality control covers all stages from raw materials to finished products, ensuring superior quality standards.

We provide detailed installation drawings and can send engineers or a complete installation team upon request.

Yes, we create complete solution drawings using professional software like AutoCAD, Tekla Structures, and others.

We maintain ISO9000, CE, and SGS certifications, ensuring international quality standards.